| Product Description | |

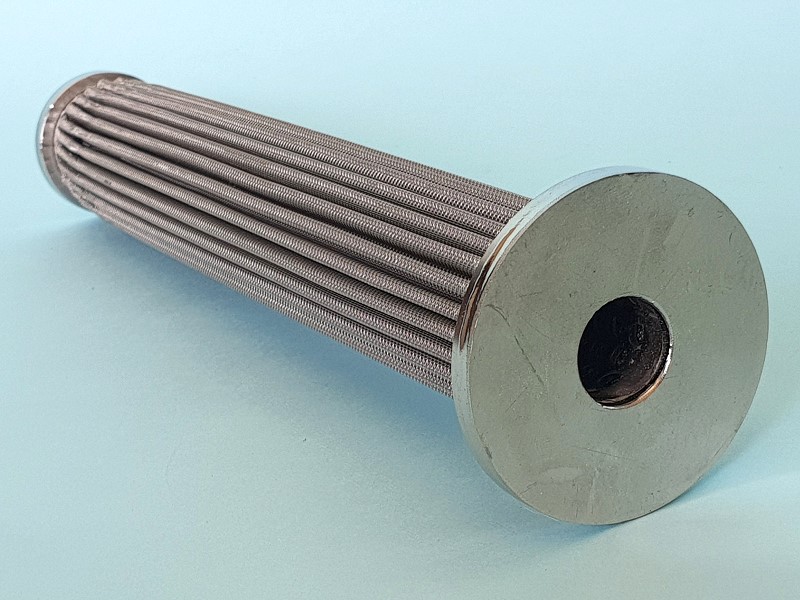

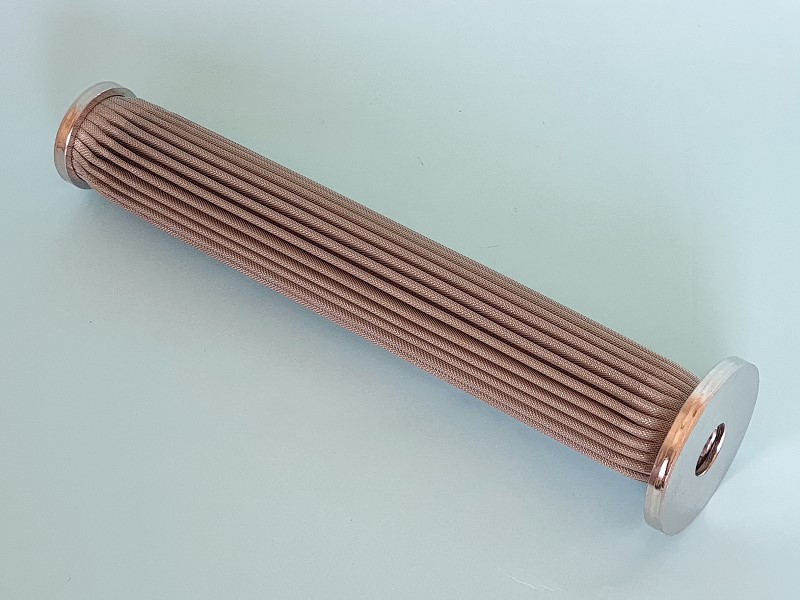

The metal film XKF element uses imported stainless steel fibers as raw materials. After non-woven laying and stacking of metal fibers, the porous depth-type filter material is made by high-temperature vacuum sintering. Its most prominent feature is its high porosity. Since the diameter of the metal fiber is very uniform, the pore size distribution is limited to a very narrow environment. Therefore, the metal fiber felt can also provide good air permeability while ensuring precise filtration accuracy. The metal fiber felt can also increase the filtering area of the filter element by folding waves, thereby increasing the amount of dirt holding. | |

| Performance characteristics | |

| |

| Product specifications | |

| |

| Scope of application | |

| |

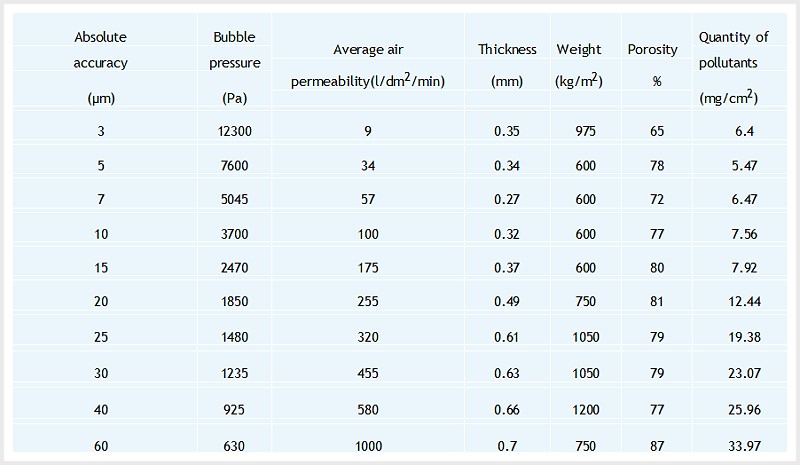

| XKF component parameter table | |

|